The mining industry operates in some of the harshest environments on earth, requiring robust and reliable equipment to ensure safety and productivity. Among the most critical components in mining operations are mining cables, which power machinery, provide communication, and ensure the safe transmission of signals in underground and surface mining applications. Huadong Cable Group as a professional cable manufacturer specializing in mining cable, our mining cable include type g cable, type G-GC cable, type SHD-GC cable, type W cable ect. we understand the stringent demands of this sector and the importance of delivering high-performance, durable, and safe cable solutions.

Key Requirements for Mining Cables

Mining cable must meet rigorous standards to withstand extreme conditions, including:

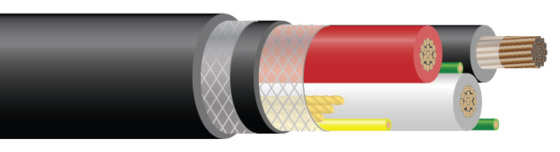

Mechanical Stress: Mining cables are frequently subjected to abrasion, crushing, and impact from heavy machinery, rock falls, and constant movement. Reinforced sheathing and flexible designs are essential to prevent damage.

Environmental Challenges: Exposure to moisture, chemicals, UV radiation (for surface mining), and temperature fluctuations demands cables with superior insulation and jacketing materials, such as EPR (Ethylene Propylene Rubber) or CSP (Chlorosulfonated Polyethylene).

Electrical Performance: High voltage and current-carrying capacity are crucial, especially for powering draglines, shuttle cars, and continuous miners. Low resistance and excellent shielding prevent energy loss and interference.

Flame Resistance & Safety: Underground mining cables must comply with MSHA (Mine Safety and Health Administration) and IEC/EN standards for flame retardancy, low smoke emission, and toxicity to ensure worker safety in confined spaces.

Types of Mining Cables

Different mining applications require specialized cables, including:

Power Supply Cables: Used for heavy-duty equipment like excavators and drills, often rated for 6/10 kV or higher with robust copper conductors and multiple layers of insulation.

Trailing Cables: Designed for flexible, repeated movement (e.g., draglines), featuring extra-flexible cores, abrasion-resistant jackets, and grounding shields.

Signal & Control Cables: Ensure reliable communication and automation in mining systems, with EMI/RFI shielding to prevent signal degradation.

Reeling & Windmill Cables: Used in vertical shaft mining or hoisting systems, engineered to withstand constant bending and tensile stress.

Innovations in Mining Cable Technology

To address evolving industry needs, manufacturers are developing advanced solutions:

Armored Cables: Steel wire or tape armor provides extra protection against crushing and rodent damage.

Oil & Chemical Resistance: Special compounds like PUR (Polyurethane) jackets resist oils and solvents commonly found in mining environments.

Smart Cables: Integrated sensors monitor real-time conditions (e.g., temperature, wear) to predict failures and reduce downtime.

Choosing the Right Mining Cable Supplier

Selecting a reliable manufacturer is critical. Key factors include:

Compliance with international standards (ISO, MSHA, IEC, UL).

Customization options for length, voltage, and environmental adaptations.

Rigorous quality testing (e.g., bend tests, flame resistance checks).

Mining cables are the lifeline of safe and efficient mining operations. As a trusted cable manufacturer, we prioritize durability, safety, and performance to meet the toughest industry challenges. Investing in high-quality mining cables not only enhances operational efficiency but also safeguards personnel and equipment in one of the world’s most demanding industries.

For mining companies seeking reliable cable solutions, partnering with an experienced manufacturer ensures uninterrupted power and communication—keeping the heart of the mine beating strong.