Application

ACSR conductors are widely used for electrical power transmission over long distances, since they are ideal for long overhead lines spans. They are also used as a messenger for supporting overhead electrical cables.

Standard

Basic design to BS 215-2 / BS EN 50182 / IEC 61089 / ASTM B 232/B 232M / DIN 48204 / JIS C 3110 standards

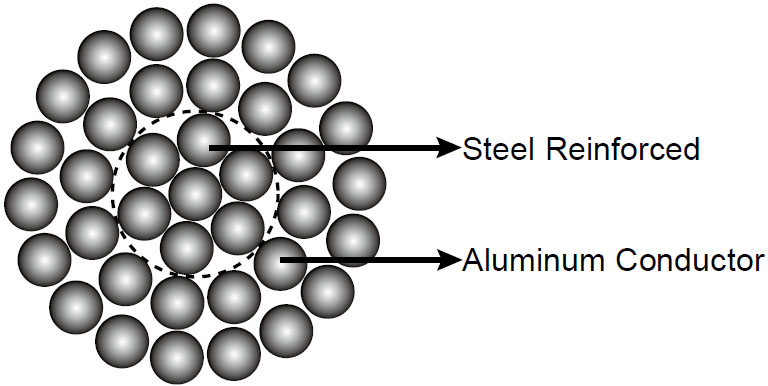

Construction

ACSR conductors are formed by several wires of aluminium and galvanized steel, stranded in concentric layers. The wire or wires which form the core, are made of galvanized steel and the external layer or layers, are of aluminium. Galvanized steel core consist normally of 1, 7 or 19 wires. The diameters of steel and aluminium wires can be the same, or different.

By varying the relative proportions of aluminium and steel, the required characteristics for any particular application can be reached. A higher U. T. S. Can be obtained, by increasing steel content, and a higher current carrying capacity by increasing aluminium content.

Electrical Properties

| Density@20oC | Aluminium: 2.703 kg/dm Galvanised Steel: 7.80 kg/dm |

| Temperature Coefficient@20°C | Aluminium: 0.00403 (°C) |

| Resistivity@20°C | Aluminium: Should not exceed 0.028264 |

| Linear Expansivity | Aluminium: 23 x10 (°C) Galvanised Steel: 11.5 x10 (1/°C) |

Service Conditions

| Ambient Temperature | -5°C – 50°C |

| Wind Pressure | 80 – 130kg/m^2 |

| Seismic Acceleration | 0.12 – 0.05g |

| Isokeraunic Level | 10 – 18 |

| Relative Humidity | 5 – 100% |

Construction Parameters

| ACSR Conductor Technical characteristics / U.S.A Sizes - ASTM B232 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Code name | Area | Stranding and diameter | Approximate overall diameter | Linear mass | Rated tensile strength | Maximum D.C. Resistance at 20℃ Ω/km | Cuttent Rating | ||||||

| Aluminum | Steel | Total | Aluminum | Steel | Aluminum | Steel | Total. | ||||||

| AWG or MCM | mm2 | mm2 | mm2 | mm | mm | mm | kg/km | kg/km | kg/km | daN | A | ||

| wren | 8 | 8.88 | 1.11 | 10.1010 | 6/1.33 | 1/1.33 | 4.44 | 23.23) | 11.11 | 34.34 | 308 | 3.33333 | 63 |

| Turkey | 6 | 13.1313 | 2.22 | 15.1515 | 6/1.68 | 1/1.68 | 5.55 | 37.37) | 17.17 | 54.54 | 524 | 2.22222 | 78 |

| Swan | 4 | 21.2121 | 4.44 | 25.2525 | 6/2.12 | 1/2.12 | 6.66 | 58.58) | 27.27 | 85.85 | 832 | 1.11111 | 105 |

| Swante | 4 | 21.2121 | 5.55 | 26.2626 | 7/1.96 | 1/2.61 | 7.77 | 58.58) | 42.42 | 100.100 | 1053 | 1.11111 | 104 |

| Swallow | 3 | 27.2727 | 4.44 | 31.3131 | 6/2.38 | 1/2.38 | 7.77 | 73.73) | 35.35 | 108.108 | 1021 | 1.11111 | 129 |

| Sparrow | 2 | 34.3434 | 6.66 | 39.3939 | 6/2.67 | 1/2.67 | 8.88 | 92.92) | 44.44 | 136.136 | 1270 | 1.11111 | 139 |

| Sparate | 2 | 34.3434 | 9.99 | 42.4242 | 7/2.47 | 1/3.30 | 8.88 | 92.92) | 67.67 | 159.159 | 1611 | 1.11111 | 138 |

| Robin | 1 | 42.4242 | 7.77 | 49.4949 | 6/3.00 | 1/3.00 | 9.99 | 116.116) | 55.55 | 171.171 | 1585 | 1.11111 | 160 |

| Raven | 0 | 53.5353 | 9.99 | 62.6262 | 6/3.37 | 1/3.37 | 10.1010 | 147.147) | 69.69 | 216.216 | 1932 | 1.11111 | 183 |

| Quail | 2/0 | 67.6767 | 11.1111 | 79.7979 | 6/3.78 | 1/3.78 | 11.1111 | 185.185) | 88.88 | 273.273 | 2362 | 0.00000 | 210 |

| Pigeon | 3/0 | 85.8585 | 14.1414 | 99.9999 | 6/4.25 | 1/4.25 | 13.1313 | 233.233) | 110.110 | 343.343 | 2941 | 0.00000 | 241 |

| Penguin | 4/0 | 107.107107 | 18.1818 | 125.125125 | 6/4.77 | 1/4.77 | 14.1414 | 294.294) | 139.139 | 433.433 | 3706 | 0.00000 | 276 |

| Waxwing | 267.267267267 | 135.135135 | 7.77 | 143.143143 | 18/3.09 | 1/3.09 | 15.1515 | 373.373) | 58.58 | 431.431 | 3027 | 0.00000 | 319 |

| Partridge | 267.267267267 | 135.135135 | 22.2222 | 157.157157 | 26/2.57 | 7/2.00 | 16.1616 | 374.374) | 172.172 | 546.546 | 5029 | 0.00000 | 323 |

| Ostrich | 300.300300300 | 152.152152 | 25.2525 | 177.177177 | 26/2.73 | 7/2.12 | 17.1717 | 421.421) | 193.193 | 614.614 | 5652 | 0.00000 | 346 |

| Merlin | 336.336336336 | 170.170170 | 9.99 | 180.180180 | 18/3.47 | 1/3.47 | 17.1717 | 470.470) | 74.74 | 544.544 | 3823 | 0.00000 | 386 |

| Linnet | 336.336336336 | 170.170170 | 28.2828 | 198.198198 | 26/2.89 | 7/2.25 | 18.1818 | 472.472) | 217.217 | 689.689 | 6271 | 0.00000 | 371 |

| Oriole | 336.336336336 | 170.170170 | 40.4040 | 210.210210 | 30/2.69 | 7/2.69 | 19.1919 | 473.473) | 311.311 | 784.784 | 7745 | 0.00000 | 372 |

| Chickadee | 398.398398398 | 201.201201 | 11. 16 | 213.213213 | 18/3.77 | 1/3.77 | 19.1919 | 555.555) | 87.87 | 642.642 | 4399 | 0.00000 | 403 |

| Brant | 398.398398398 | 201.201201 | 26.2626 | 228.228228 | 24/3.27 | 7/2.18 | 20.2020 | 558.558) | 204.204 | 762.762 | 6469 | 0.00000 | 405 |

| Ibis | 398.398398398 | 201.201201 | 33.3333 | 234.234234 | 26/3.14 | 7/2.44 | 20.2020 | 558.558) | 256.256 | 814.814 | 7211 | 0.00000 | 403 |

| Lark | 398.398398398 | 201.201201 | 47.4747 | 248.248248 | 30/2.92 | 7/2.92 | 20.2020 | 560.560) | 367.367 | 927.927 | 8869 | 0.00000 | 410 |

| Pelican | 477.477477477 | 242.242242 | 13.1313 | 255.255255 | 18/4.12 | 1/4.14 | 21.2121 | 666.666) | 105.105 | 771.771 | 5216 | 0.00000 | 449 |

| Flicker | 477.477477477 | 242.242242 | 31.3131 | 273.273273 | 24/3.58 | 7/2.39 | 21.2121 | 670.670) | 245.245 | 915.915 | 7666 | 0.00000 | 454 |

| Hawk | 477.477477477 | 242.242242 | 39.3939 | 281.281281 | 26/3.44 | 7/2.67 | 22.2222 | 670.670) | 308.308 | 978.978 | 8665 | 0.00000 | 455 |

| Hen | 477.477477477 | 242.242242 | 56.5656 | 298.298298 | 30/3.20 | 7/3.20 | 22.2222 | 671.671) | 441.441 | 1112.1112 | 10534 | 0.00000 | 457 |

| Osprey | 556.556556556 | 282.282282 | 16.1616 | 298.298298 | 18/4.47 | 1/4.47 | 22.2222 | 777.777) | 122.122 | 899.899 | 6088 | 0.00000 | 492 |

| Parakeet | 556.556556556 | 282.282282 | 37.3737 | 319.319319 | 24/3.87 | 7/2.58 | 23.2323 | 781.781) | 286.286 | 1067.1067 | 8822 | 0.00000 | 492 |

| Dove | 556.556556556 | 282.282282 | 46.4646 | 328.328328 | 26/3.72 | 7/2.89 | 24.2424 | 781.781) | 359.359 | 1140.1140 | 10103 | 0.00000 | 499 |

| Eagle | 556.556556556 | 282.282282 | 66.6666 | 348.348348 | 30/3.46 | 7/3.46 | 24.2424 | 783.783) | 515.515 | 1298.1298 | 13392 | 0.00000 | 500 |

| Peacock | 605.605605605 | 307.307307 | 40.4040 | 346.346346 | 24/4.03 | 7/2.69 | 24.2424 | 849.849) | 311.311 | 1160.1160 | 9588 | 0.00000 | 522 |

| Squab | 605.605605605 | 307.307307 | 50.5050 | 357.357357 | 26/3.87 | 7/3.01 | 25.2525 | 850.850) | 390.390 | 1240.1240 | 10841 | 0.00000 | 523 |

| Wood duck | 605.605605605 | 307.307307 | 72.7272 | 378.378378 | 30/3.16 | 7/3.61 | 25.2525 | 851.851) | 560.560 | 1411.1411 | 12884 | 0.00000 | 523 |

| Teal | 605.605605605 | 307.307307 | 70.7070 | 376.376376 | 30/3.61 | 19/2.16 | 25.2525 | 851.851) | 548.548 | 1399.1399 | 13359 | 0.00000 | 527 |

| Kingbird | 636.636636636 | 322.322322 | 18.1818 | 340.340340 | 18/4.78 | 1/4.78 | 24.2424 | 889.889) | 139.139 | 1028.1028 | 6956 | 0.00000 | 530 |

| Rook | 636.636636636 | 322.322322 | 42.4242 | 364.364364 | 24/4.14 | 7/2.76 | 25.2525 | 893.893) | 326.326 | 1219.1219 | 10083 | 0.00000 | 537 |

| Grosbeak | 636.636636636 | 322.322322 | 52.5252 | 375.375375 | 26/3.97 | 7/3.09 | 25.2525 | 893.893) | 409.409 | 1302.1302 | 11180 | 0.00000 | 538 |

| Scoter | 636.636636636 | 322.322322 | 75.7575 | 394.394394 | 30/3.70 | 7/3.70 | 26.2626 | 895.895) | 589.589 | 1484.1484 | 13544 | 0.00000 | 541 |

| Egret | 636.636636636 | 322.322322 | 74.7474 | 396.396396 | 30/3.70 | 19/2.22 | 26.2626 | 894.894) | 576.576 | 1470.1470 | 14055 | 0.00000 | 542 |

| Swift | 636.636636636 | 322.322322 | 9.99 | 331.331331 | 36/3.38 | 1/3.38 | 24.2424 | 888.888) | 70.70 | 958.958 | 6052 | 0.00000 | 545 |

| Flamingo | 667.667667667 | 338.338338 | 44.4444 | 382.382382 | 24/4.23 | 7/2.82 | 25.2525 | 936.936) | 342.342 | 1278.1278 | 10566 | 0.00000 | 552 |

| Gannet | 667.667667667 | 338.338338 | 55.5555 | 393.393393 | 26/4.07 | 7/3.16 | 26.2626 | 936.936) | 429.429 | 1365.1365 | 11733 | 0.00000 | 618 |

| Stilt | 716.716716716 | 363.363363 | 47.4747 | 410.410410 | 24/4.39 | 7/2.92 | 26.2626 | 1005.1005) | 367.367 | 1372.1372 | 11335 | 0.00000 | 577 |

| Starling | 716.716716716 | 363.363363 | 59.5959 | 422.422422 | 26/4.21 | 7/3.28 | 27.2727 | 1005.1005) | 461.461 | 1466.1466 | 12591 | 0.00000 | 578 |

| Redwing | 716.716716716 | 363.363363 | 83.8383 | 445.445445 | 30/3.92 | 19/2.35 | 27.2727 | 1006.1006) | 647.647 | 1653.1653 | 15394 | 0.00000 | 581 |

| Tern | 795.795795795 | 403.403403 | 28.2828 | 431.431431 | 45/3.38 | 7/2.25 | 27.2727 | 1116.1116) | 217.217 | 1333.1333 | 9737 | 0.00000 | 610 |

| Condor | 795.795795795 | 403.403403 | 52.5252 | 455.455455 | 54/3.08 | 7/3.08 | 28.2828 | 1116.1116) | 408.408 | 1524.1524 | 12445 | 0.00000 | 614 |

| Cuckoo | 795.795795795 | 403.403403 | 52.5252 | 455.455455 | 24/4.62 | 7/3.08 | 28.2828) | 1116.1116) | 408.408 | 1522.1522 | 12394 | 0.00000 | 614 |

| Drake | 795.795795795 | 402.84 | 66.6666 | 468.468468 | 26/4.44 | 7/3.45 | 28.2828) | 1116.1116) | 518 | 1628 | 13992 | 0.07191 | 614 |

| Coot | 795.795795795 | 402.84 | 11.1111 | 414.414414 | 36/3.77 | 1/3.77 | 26.2626) | 1110.1110) | 88 | 1198 | 7485 | 0.07156 | 614 |

| Mallard | 795.795795795 | 403.403403 | 92.9292 | 485.485485 | 30/4.14 | 19/2.48 | 29.2929) | 1119.1119) | 719 | 1838 | 17118 | 0.07208 | 618 |

| Ruddy | 900.900900900 | 456.456456 | 32.3232 | 488.488488 | 45/3.59 | 7/2.40 | 29.2929) | 1263.1263) | 247 | 1510 | 10931 | 0.06351 | 656 |

| Canary | 900.900900900 | 456.456456 | 59.5959 | 515.515515 | 54/3.28 | 7/3.28 | 30.3030) | 1263.1263) | 461 | 1724 | 14095 | 0.06351 | 660 |

| Rail | 954.954954954 | 483.483483 | 33.3333 | 517.517517 | 45/3.70 | 7/2.47 | 30.3030) | 1339.1339) | 262 | 1601 | 11585 | 0.05992 | 679 |

| Catbird | 954.954954954 | 483.483483 | 13.1313 | 496. 84 | 36/4.14 | 1/4.14 | 29.2929) | 1333.1333) | 105 | 1438 | 8766 | 0.00000 | 679 |

| Cardinal | 954.954954954 | 483.483483 | 63.6363 | 546. 07 | 54/3.38 | 7/3.38 | 30.3030) | 1339.1339) | 490 | 1829 | 14936 | 0.00000 | 681 |

| Ortolan | 1034.103410341034 | 524.524524 | 36.3636 | 559. 87 | 45/3.85 | 7/2.57 | 31.3131) | 1451.1451) | 283 | 1734 | 12310 | 0.00000 | 712 |

| Tanager | 1034.103410341034 | 524.524524 | 15.1515 | 538.538538 | 36/4.30 | 1/4.30 | 30.3030) | 1443.1443) | 113 | 1556 | 9493 | 0.00000 | 705 |

| Curlew | 1034.103410341034 | 524.524524 | 68.6868 | 592.592592 | 54/3.52 | 7/3.52 | 32.3232) | 1451.1451) | 530 | 1981 | 16180 | 0.00000 | 715 |

| Bluejay | 1113.111311131113 | 564.564564 | 39.3939 | 603.603603 | 45/4.00 | 7/2.66 | 32.3232) | 1563.1563) | 385 | 1868 | 13263 | 0.00000 | 743 |

| Finch. | 1113.111311131113 | 564.564564 | 72.7272 | 635.635635 | 54/3.65 | 19/2.19 | 33.3333) | 1570.1570) | 580 | 2130 | 17441 | 0.00000 | 746 |

| Bunting | 1192.119211921192 | 604.604604 | 42.4242 | 646.646646 | 48/4.14 | 7/2.76 | 33.3333) | 1674.1674) | 327 | 2001 | 14179 | 0.00000 | 772 |

| Grackle | 1192.119211921192 | 604.604604 | 77.7777 | 681.681681 | 54/3.77 | 19/2.27 | 34.3434) | 1682.1682) | 600 | 2282 | 18678 | 0.00000 | 773 |

| Bittern | 1272.127212721272 | 645.645645 | 45.4545 | 689.689689 | 45/4.27 | 7/2.85 | 34.3434) | 1785.1785) | 349 | 2134 | 15148 | 0.00000 | 802 |

| Pheasant | 1272.127212721272 | 645.645645 | 82.8282 | 726.726726 | 54/3.90 | 19/2.34 | 35.3535) | 1795.1795) | 638 | 2433 | 19400 | 0.00000 | 807 |

| Skylark | 1272.127212721272 | 645.645645 | 18.1818 | 662.662662 | 36/4.78 | 1/4.78 | 33.3333) | 1777.1777) | 140 | 1917 | 11585 | 0.00000 | 807 |

| Dipper | 1352.135213521352 | 685.685685 | 47.4747 | 732.732732 | 45/4.40 | 7/2.92 | 35.3535) | 1898.1898) | 368 | 2266 | 16070 | 0.00000 | 831 |

| Martin | 1352.135213521352 | 685.685685 | 89.8989 | 772.772772 | 54/4.02 | 19/2.41 | 36.3636) | 1906.1906) | 679 | 2585 | 20605 | 0.00000 | 835 |

| Bobolink | 1431.143114311431 | 725.725725 | 50.5050 | 775.775775 | 45/4.53 | 7/3.02 | 36.3636) | 2009.2009) | 393 | 2402 | 17071 | 0.00000 | 859 |

| Plover | 1431.143114311431 | 725.725725 | 92.9292 | 817.817817 | 54/4.14 | 19/2.48 | 37.3737) | 2019.2019) | 719 | 2738 | 21824 | 0.00000 | 862 |

| Nuthatch | 1510.151015101510 | 765.765765 | 53.5353 | 818.818818 | 45/4.65 | 7/3.10 | 37.3737) | 2120.2120) | 414 | 2534 | 17789 | 0.00000 | 886 |

| Parrot | 1510.151015101510 | 765.765765 | 97.9797 | 862.862862 | 54/4.25 | 19/2.55 | 38.3838) | 2131.2131) | 759 | 2890 | 23020 | 0.00000 | 890 |

| Lapwing | 1590.159015901590 | 806.806806 | 55.5555 | 861.861861 | 45/4.77 | 7/3.18 | 38.3838) | 2232.2232) | 435 | 2667 | 18702 | 0.00000 | 911 |

| Falcon | 1590.159015901590 | 806.806806 | 102.102102 | 908.908908 | 54/4.36 | 19/2.62 | 39.3939) | 2243.2243) | 799 | 3042 | 24255 | 0.00000 | 917 |

| Chukar | 1780.178017801780 | 903.903903 | 74.7474 | 903.903903 | 84/3.70 | 19/2.22 | 41.4141) | 2511.2511) | 575 | 3086 | 22685 | 0.00000 | 975 |

| BlueBird | 2156.215621562156 | 1092.10921092 | 89.8989 | 1092.10921092 | 84/4.07 | 19/2.44 | 45.4545) | 3036.3036) | 697 | 3733 | 26830 | 0.00000 | 1180 |

| Kiwi | 2167.216721672167 | 1100.11001100 | 48.4848 | 1099.10991099 | 72/4.41 | 7/2.94 | 44.4444) | 3057.3057) | 370 | 3427 | 22160 | 0.00000 | 1188 |

| Thrasher | 2312.231223122312 | 1171.11711171 | 65.6565 | 1171.11711171 | 76/4.43 | 19/2.09 | 46.4646) | 3256.3256) | 511 | 3767 | 25300 | 0.00000 | 1260 |

| Grouse | 80.808080 | 41.4141 | 14.1414 | 55.5555 | 8/2.54 | 1/4.24 | 9.99) | 112.112) | 110 | 222 | 2360 | 1.11111 | 155 |

| Petrel | 102.102102102 | 52.5252 | 30.3030 | 82.8282 | 12/2.34 | 7/2.34 | 12.1212) | 143.143) | 235 | 378 | 4715 | 1.11111 | 187 |

| Minorca | 111.111111111 | 56.5656 | 33.3333 | 89.8989 | 12/2.44 | 7/2.44 | 12.1212) | 156.156) | 256 | 412 | 5125 | 1.11111 | 197 |

| Leghorn | 135.135135135 | 68.6868 | 40.4040 | 108.108108 | 12/2.69 | 7/2.69 | 13.1313) | 189.189) | 311 | 500 | 6170 | 0.00000 | 221 |

| Guinea | 159.159159159 | 81.8181 | 47.4747 | 128.128128 | 12/2.92 | 7/2.92 | 15.1515) | 223.223) | 367 | 590 | 7255 | 0.00000 | 244 |

| Dotterel | 177.177177177 | 89.8989 | 52.5252 | 142.142142 | 12/3.08 | 7/3.08 | 15.1515) | 248.248) | 409 | 657 | 7850 | 0.00000 | 260 |

| Dorking | 191.191191191 | 97.9797 | 56.5656 | 153.153153 | 12/3.20 | 7/3.20 | 16.1616) | 268.268) | 441 | 709 | 8480 | 0.00000 | 272 |

| Brahma | 203.203203203 | 103.103103 | 92.9292 | 195.195195 | 16/2.86 | 19/2.48 | 18.1818) | 285.285) | 722 | 1007 | 12880 | 0.00000 | 288 |

| Cochin | 211.211211211 | 107.107107 | 62.6262 | 170.170170 | 12/3.37 | 7/3.37 | 17.1717) | 297.297) | 488 | 765 | 9390 | 0.00000 | 287 |

Please check the specification, our competitive price will send you in 12 hours.

| ACSR Conductor Technical Characteristics / BS215 Standard | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Code name | Nominal aluminum area mm2 | Stranding structure | Sectional area of aluminum | Total sectional area | Overall diameter | Calculated breaking load | Calculate D.C resistance at 20℃ | Current Rating | ||||

| Total | ||||||||||||

| Al. No. | Al. Dia. | St. No. | St. Dia | mm2 | mm2 | mm | kg/km | daN | Ω/km | A | ||

| Mole | 10 | 6 | 2.22 | 1 | 2.22 | 11.1111 | 12.1212 | 4.44 | 43 | 414 | 3.3333 | 67 |

| Squirrel | 20 | 6 | 2.22 | 1 | 2.22 | 21.2121 | 24.2424 | 6.66 | 85 | 788 | 1.1111 | 109 |

| Gopher | 25 | 6 | 2.22 | 1 | 2.22 | 26.2626 | 31.3131 | 7.77 | 106 | 961 | 1.1111 | 126 |

| Weasel | 30 | 6 | 3.33 | 1 | 3.33 | 32.3232 | 37.3737 | 8.88 | 128 | 1146 | 1.1111 | 134 |

| Fox | 35 | 6 | 3.33 | 1 | 3.33 | 37.3737 | 43.4343 | 8.88 | 149 | 1320 | 1.1111 | 147 |

| Ferret | 40 | 6 | 3.33 | 1 | 3.33 | 42.4242 | 49.4949 | 9.99 | 172 | 1520 | 1.1111 | 161 |

| Rabbit | 50 | 6 | 3.33 | 1 | 3.33 | 53.5353 | 62.6262 | 10.1010 | 214 | 1835 | 1.1111 | 185 |

| Mink | 60 | 6 | 4.44 | 1 | 4.44 | 63.6363 | 74.7474 | 11.1111 | 255 | 2180 | 0.0000 | 174 |

| Skunk | 60 | 12 | 3.33 | 7 | 3.33 | 63.6363 | 100.100100 | 13.1313 | 465 | 5300 | 0.0000 | 246 |

| Beaver | 70 | 6 | 4.44 | 1 | 4.44 | 75.7575 | 87.8787 | 12.1212 | 302 | 2570 | 0.0000 | 193 |

| Horse | 70 | 12 | 3.33 | 7 | 3.33 | 73.7373 | 116.116116 | 14.1414 | 538 | 6120 | 0.0000 | 268 |

| Racoon | 75 | 6 | 4.44 | 1 | 4.44 | 79.7979 | 92.9292 | 12.1212 | 320 | 2720 | 0.0000 | 231 |

| Otter | 80 | 6 | 4.44 | 1 | 4.44 | 84.8484 | 98.9898 | 14.1414 | 339 | 2880 | 0.0000 | 240 |

| Cat | 90 | 6 | 4.44 | 1 | 4.44 | 95.9595 | 111.111111 | 16.1616 | 386 | 3270 | 0.0000 | 248 |

| Hare | 100 | 6 | 5.55 | 1 | 5.55 | 105.105105 | 122.122122 | 18.1818 | 425 | 3600 | 0.0000 | 273 |

| Dog | 100 | 6 | 5.55 | 7 | 2.22 | 105.105105 | 118.118118 | 14.1414 | 394 | 3270 | 0.0000 | 278 |

| Hyena | 100 | 7 | 4.44 | 7 | 2.22 | 106.106106 | 126.126126 | 15.1515 | 450 | 4090 | 0.0000 | |

| Leopard | 125 | 8 | 5.55 | 7 | 2.22 | 131.131131 | 148.148148 | 16.1616 | 492 | 4070 | 0.0000 | |

| Coyote | 125 | 26 | 3.33 | 7 | 2.22 | 132.132132 | 152.152152 | 16.1616 | 522 | 4640 | 0.0000 | 311 |

| Congar | 125 | 18 | 3.33 | 1 | 3.33 | 130.130130 | 138.138138 | 15.1515 | 419 | 2980 | 0.0000 | 314 |

| Tiger | 125 | 30 | 2.22 | 7 | 2.22 | 131.131131 | 162.162162 | 17.1717 | 602 | 5800 | 0.0000 | 323 |

| Dingo | 150 | 18 | 3.33 | 1 | 3.33 | 159.159159 | 168.168168 | 17.1717 | 506 | 3570 | 0.0000 | 349 |

| Wolf | 150 | 30 | 3.33 | 7 | 3.33 | 158.158158 | 195.195195 | 18.1818 | 726 | 6920 | 0.0000 | 355 |

| Caracal | 175 | 18 | 4.44 | 1 | 4.44 | 184.184184 | 194.194194 | 18.1818 | 587 | 4110 | 0.0000 | 383 |

| Lynx | 175 | 30 | 3.33 | 7 | 3.33 | 183.183183 | 326.326326 | 20.2020 | 842 | 7980 | 0.0000 | 386 |

| Jaguar | 200 | 18 | 4.44 | 1 | 4.44 | 211.211211 | 222.222222 | 19.1919 | 671 | 4655 | 0.0000 | 415 |

| Panther | 200 | 30 | 3.33 | 7 | 3.33 | 212.212212 | 262.262262 | 21.2121 | 974 | 9225 | 0.0000 | 421 |

| Lion | 225 | 30 | 3.33 | 7 | 3.33 | 238.238238 | 294.294294 | 22.2222 | 1095 | 10060 | 0.0000 | 448 |

| Bear | 250 | 30 | 3.33 | 7 | 3.33 | 264.264264 | 326.326326 | 23.2323 | 1213 | 11110 | 0.0000 | 481 |

| Goat | 300 | 30 | 4.44 | 7 | 4.44 | 324.324324 | 400.400400 | 26.2626 | 1489 | 13570 | 0.0000 | 542 |

| Sheep | 350 | 30 | 4.44 | 7 | 4.44 | 374.374374 | 461.461461 | 28.2828 | 1718 | 15590 | 0.0000 | 592 |

| Antilope | 350 | 54 | 3.33 | 7 | 3.33 | 373.373373 | 422.422422 | 27.2727 | 1411 | 11820 | 0.0000 | 588 |

| Bizon | 350 | 54 | 3.33 | 7 | 3.33 | 382.382382 | 431.431431 | 27.2727 | 1444 | 12090 | 0.0000 | 595 |

| Deer | 400 | 30 | 4.44 | 7 | 4.44 | 429.429429 | 530.530530 | 29.2929 | 1971 | 17850 | 0.0000 | 639 |

| Zebra | 400 | 54 | 3.33 | 7 | 3.33 | 429.429429 | 484.484484 | 29.2929 | 1621 | 13190 | 0.0000 | 635 |

| ELK | 450 | 30 | 4.44 | 7 | 4.44 | 477.477477 | 588.588588 | 32.3232 | 2190 | 19820 | 0.0000 | 679 |

| Camel | 450 | 54 | 3.33 | 7 | 3.33 | 475.475475 | 537.537537 | 30.3030 | 1777 | 14570 | 0.0000 | 677 |

| Moose | 500 | 54 | 4.44 | 7 | 4.44 | 529.529529 | 597.597597 | 32.3232 | 1999 | 16110 | 0.0000 | 763 |

| Finch | 500 | 54 | 4.44 | 19 | 2.22 | 565.565565 | 643.643643 | 33.3333 | 2243 | 18070 | 0.0000 | 815 |

Please check the specification, our competitive price will send you in 12 hours.

| ACSR Technical characteristics / ACSR-IEC1089-A1/S2A | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Code number | Area | Number of wires | Wire dia. | Diameter | Linear Mass | Rated Strength | D.C. Resistance | |||||

| Alum | Steel | Total | Alum. | Steel | Core | Cond. | ||||||

| mm2 | mm2 | mm2 | Al | St | mm | mm | mm | mm | kg/km | kN | Ω/km | |

| 16 | 16 | 3.33 | 19.1919 | 6 | 1 | 2.22 | 2.22 | 2.22 | 6.66 | 64.6464 | 6.66 | 2.2222 |

| 25 | 25 | 4.44 | 29.2929 | 6 | 1 | 2.22 | 2.22 | 2.22 | 7.77 | 101.101101 | 10.1010 | 1.1111 |

| 40 | 40 | 7.77 | 47.4747 | 6 | 1 | 3.33 | 3.33 | 3.33 | 9.99 | 162.162162 | 15.1515 | 1.1111 |

| 63 | 63 | 10.1010 | 74.7474 | 6 | 1 | 4.44 | 4.44 | 4.44 | 11.1111 | 254.254254 | 22.2222 | 0.0000 |

| 100 | 100 | 17.1717 | 117.117117 | 6 | 1 | 5.55 | 5.55 | 5.55 | 14.1414 | 404.404404 | 36.3636 | 0.0000 |

| 125 | 125 | 7.77 | 132.132132 | 18 | 1 | 3.33 | 3.33 | 3.33 | 15.1515 | 398.398398 | 30.3030 | 0.0000 |

| 125 | 125 | 20.2020 | 145.145145 | 26 | 7 | 2.22 | 2.22 | 6.66 | 16.1616 | 504.504504 | 49.4949 | 0.0000 |

| 160 | 160 | 9.99 | 169.169169 | 18 | 1 | 3.33 | 3.33 | 3.33 | 17.1717 | 508.508508 | 37.3737 | 0.0000 |

| 160 | 160 | 26.2626 | 186.186186 | 26 | 7 | 3.33 | 7.77 | 7.77 | 18.1818 | 645.645645 | 61.6161 | 0.0000 |

| 200 | 200 | 11.1111 | 211.211211 | 18 | 7 | 4.44 | 4.44 | 4.44 | 19.1919 | 637.637637 | 45.4545 | 0.0000 |

| 200 | 200 | 33.3333 | 233.233233 | 26 | 1 | 3.33 | 7.77 | 7.77 | 20.2020 | 806.806806 | 75.7575 | 0.0000 |

| 250 | 250 | 25.2525 | 275.275275 | 22 | 7 | 4.44 | 6.66 | 6.66 | 22.2222 | 881.881881 | 72.7272 | 0.0000 |

| 250 | 250 | 41.4141 | 291.291291 | 26 | 7 | 4.44 | 8.88 | 8.88 | 22.2222 | 1008.10081008 | 93.9393 | 0.0000 |

| 315 | 315 | 22.2222 | 337.337337 | 45 | 7 | 3.33 | 6.66 | 6.66 | 24.2424 | 1039.10391039 | 82.8282 | 0.0000 |

| 315 | 315 | 51.5151 | 366.366366 | 26 | 7 | 4.44 | 9.99 | 9.99 | 25.2525 | 1270.12701270 | 114.114114 | 0.0000 |

| 400 | 400 | 28.2828 | 428.428428 | 45 | 7 | 3.33 | 7.77 | 7.77 | 27.2727 | 1320.13201320 | 102. 23 | 0.0000 |

| 400 | 400 | 52.5252 | 452.452452 | 54 | 7 | 3.33 | 9.99 | 9.99 | 28.2828 | 1510.15101510 | 130.130130 | 0.0000 |

| 450 | 450 | 31.3131 | 481.481481 | 45 | 7 | 4.44 | 7.77 | 7.77 | 28.2828 | 1485.14851485 | 112.112112 | 0.0000 |

| 450 | 450 | 58.5858 | 508.508508 | 54 | 7 | 3.33 | 10.1010 | 10.1010 | 29.2929 | 1699.16991699 | 147.147147 | 0.0000 |

| 500 | 500 | 35.3535 | 535.535535 | 45 | 7 | 4.44 | 8.88 | 8.88 | 30.3030 | 1650.16501650 | 124.124124 | 0.0000 |

| 500 | 500 | 65.6565 | 565.565565 | 54 | 7 | 3.33 | 10.1010 | 10.1010 | 31.3131 | 1888.18881888 | 163.163163 | 0.0000 |

| 560 | 560 | 39.3939 | 599.599599 | 45 | 7 | 4.44 | 8.88 | 8.88 | 32.3232 | 1848.18481848 | 139.139139 | 0.0000 |

| 560 | 560 | 71.7171 | 631.631631 | 54 | 19 | 4.44 | 11.1111 | 11.1111 | 33.3333 | 2103.21032103 | 183.183183 | 0.0000 |

| 630 | 630 | 44.4444 | 674.674674 | 45 | 7 | 4.44 | 8.88 | 8.88 | 34.3434 | 2079.20792079 | 157.157157 | 0.0000 |

| 630 | 630 | 80.8080 | 710.710710 | 54 | 19 | 4.44 | 12.1212 | 12.1212 | 35.3535 | 2366.23662366 | 203.203203 | 0.0000 |

| 710 | 710 | 49.4949 | 759.759759 | 45 | 7 | 4.44 | 9.99 | 9.99 | 36.3636 | 2343.23432343 | 176.176176 | 0.0000 |

| 710 | 710 | 90.9090 | 800.800800 | 54 | 19 | 4.44 | 12.1212 | 12.1212 | 37.3737 | 2667.26672667 | 229.229229 | 0.0000 |

| 800 | 800 | 35.3535 | 835.835835 | 72 | 7 | 4.44 | 8.88 | 8.88 | 38.3838 | 2480.24802480 | 172.172172 | 0.0000 |

| 800 | 800 | 67.6767 | 867.867867 | 84 | 7 | 3.33 | 10.1010 | 10.1010 | 38.3838 | 2733.27332733 | 215.215215 | 0.0000 |

| 800 | 800 | 101.101101 | 901.901901 | 54 | 19 | 4.44 | 13.1313 | 13.1313 | 39.3939 | 3005.30053005 | 258.258258 | 0.0000 |

| 900 | 900 | 39.3939 | 939.939939 | 72 | 7 | 4.44 | 8.88 | 8.88 | 40.4040 | 2790.27902790 | 194.194194 | 0.0000 |

| 900 | 900 | 75.7575 | 975.975975 | 84 | 7 | 4.44 | 11.1111 | 11.1111 | 41.4141 | 3074.30743074 | 232.232232 | 0.0000 |

| 1000 | 1000 | 43.4343 | 1043.10431043 | 72 | 7 | 4.44 | 8.88 | 8.88 | 42.4242 | 3100.31003100 | 215.215215 | 0.0000 |

| 1120 | 1120 | 47.4747 | 1167.11671167 | 72 | 19 | 4.44 | 9.99 | 9.99 | 44.4444 | 3465.34653465 | 241.241241 | 0.0000 |

| 1120 | 1120 | 91.9191 | 1211.12111211 | 84 | 19 | 4.44 | 12.1212 | 12.1212 | 45.4545 | 3812.38123812 | 296.296296 | 0.0000 |

| 1250 | 1250 | 53.5353 | 1303.13031303 | 72 | 19 | 5.55 | 9.99 | 9.99 | 47.4747 | 3867.38673867 | 269.269269 | 0.0000 |

| 1250 | 1250 | 102.102102 | 1352.13521352 | 84 | 19 | 4.44 | 13.1313 | 13.1313 | 48.4848 | 4254.42544254 | 330.330330 | 0.0000 |

Please check the specification, our competitive price will send you in 12 hours.